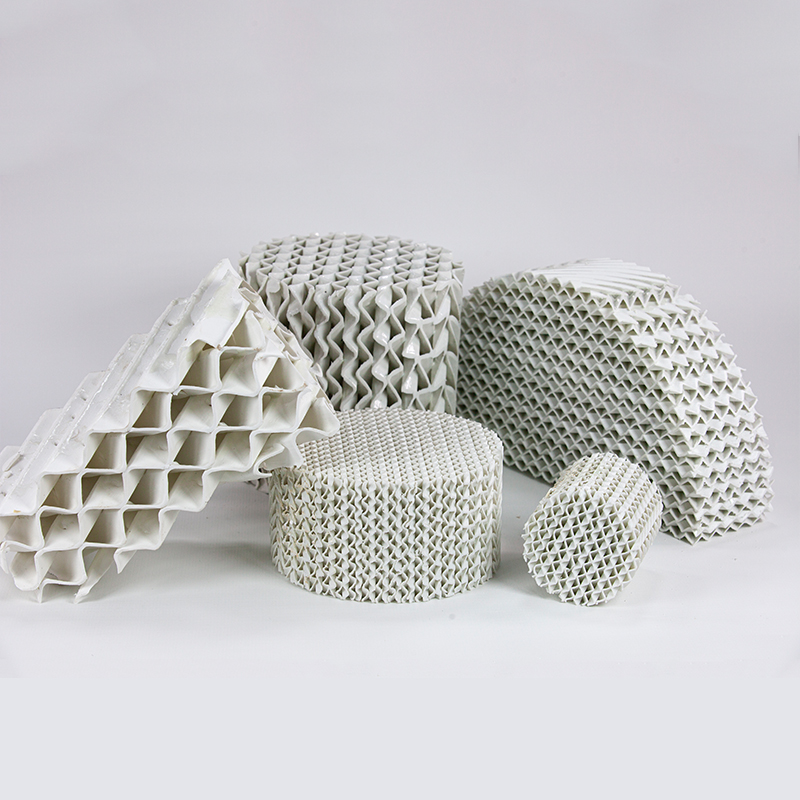

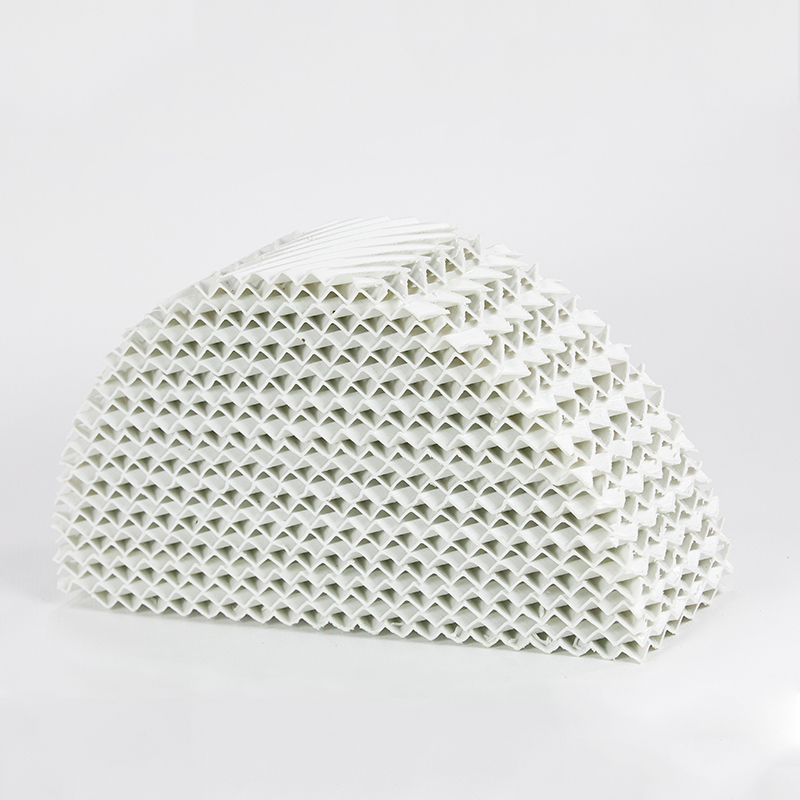

I-Ceramic Structure Packing enohlobo lwe-125Y & 250Y

Ngenxa yesakhiwo esiyingqayizivele se-ceramic, ukusebenza kahle kwe-hydrophilic, ingaphezulu layo lingakha ifilimu eliwuketshezi elincanyana kakhulu lokunyakaziswa komoya okunyakazayo kanye namashaneli ahlukumezayo angakhuthaza umoya kodwa angayeki ukufanisa umoya wokugcwalisa insimbi ungenza ukupakishwa kwe-ceramic, kanye nokumelana nokugqwala kwayo, ukusebenza kokumelana nokushisa okuphezulu kwe-metal filler akukwazi ukuqhathaniswa. ukushisa ngokweqile, ukuhlanganisa, kanye ne-coking.Lo mkhiqizo wenziwe ngekhwalithi ephezulu yamakhemikhali e-porcelain yobumba ukucubungula impahla eluhlaza futhi ube, ukumelana nokushisa okuphezulu nokucindezela okuphezulu, ukuqina okuhle kwamakhemikhali namandla aphezulu, uyisithwali esifanelekile sokusekela izinhlobo ezihlukahlukene zama-catalysts.

Ukuhlaziywa Kwamakhemikhali

| Ukwakheka | Inani |

| SiO2 | ≥72% |

| Fe2O3 | ≤0.5% |

| I-CaO | ≤1.0% |

| Al2O3 | ≥23% |

| MgO | ≤1.0% |

| Okunye | 2% |

Impahla Engokomzimba

| Inkomba | Inani |

| Amandla adonsela phansi athile(g/cm3) | 2.5 |

| Ukumuncwa kwamanzi (wt%) | ≤0.5 |

| Ukumelana ne-Acid (wt%) | ≥99.5 |

| Ukulahlekelwa ekushiseni (wt%) | ≤5.0 |

| Ubukhulu. Izinga lokushisa elisebenzayo.(℃) | 800 |

| Amandla okuchoboza (Mpa) | ≥130 |

| Ukuqina kuka-Moh(Isikali) | ≥7 |

Usuku Lokusebenza

| Ukucaciswa. | Indawo ethile (m2/m3) | Ukuminyana kwenqwaba (kg/m3) | Isilinganiso esingenalutho (%) | Obl. I-engeli | Ukwehla kwengcindezi (mm Hg/m) | Theo. Ipuleti (m-1) | Ububanzi be-Hydraulic (mm) | Umthamo woketshezi (m3/m2h) | Ubukhulu. I-Factor m/s (Kg/m3)-1 |

| 125Y | 125 | 320 | 90 | 45 | 1.8 | 1.8 | 28 | 0.2-100 | 3.0 |

| 250Y | 250 | 420 | 80 | 45 | 2 | 2.5 | 12 | 0.2-100 | 2.6 |

| 350Y | 350 | 470 | 78 | 45 | 2.5 | 2.8 | 10 | 0.2-100 | 2.5 |

| 450Y | 450 | 520 | 72 | 45 | 4 | 4 | 7 | 0.2-100 | 1.8 |

| 550Y | 550 | 620 | 74 | 45 | 5.5 | 5-6 | 6 | 0.18-100 | 1.4 |

| 700Y | 700 | 650 | 72 | 45 | 6 | 7 | 5 | 0.15-100 | 1.3 |