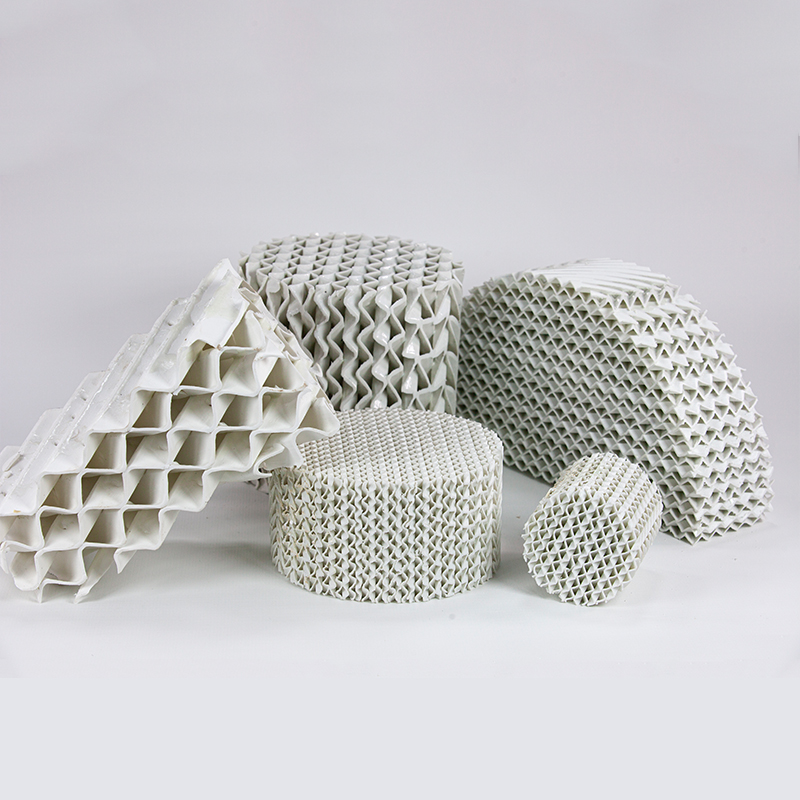

Ukumelana Nokushisa Kwefekthri Kuhlanganiswe Ukupakisha Okukhanyayo Kwe-Cermaic kwe-scrubber Tower

| Usayizi | X-01 | X-11 | X-12 | X-13 | X-14 |

| Ububanzi bangaphandle(mm) | 220±25 | 220±25 | 220±25 | 220±25 | 220±25 |

| Isikhala(mm) | 20 | 20 | 20 | 20 | 20 |

| Usayizi wembobo(mm) | 65 | 65 | 65 | 65 | 65 |

| Indawo engaphezulu(m2/m3) | 118 | 128 | 135 | 132 | 148 |

| Ivolumu yamahhala(%) | 85 | 75 | 72 | 75 | 73 |

| Ukuminyana kwenqwaba(kg/m3) | 280 | 320 | 340 | 300 | 348 |

Izinzuzo zokusebenzisa amaphakethe e-ceramic alula ami kanje:

1. Umkhiqizo unama-micropores athuthuke kahle kanye nekhono eliqinile lokunamathela kanye nokukhangisa ukungcola; Ukungena kwegesi okuphezulu, ama-micropores athuthuke kahle, namandla amahle. Ihlala isikhathi eside ekuphathweni, umthelela, nokugeleza komoya. I-porosity yayo esobala ingu-≥ 15%, futhi inamandla okunamathela aqinile nekhono lokukhanga ngokungcola okuhlukahlukene kwegesi, uketshezi kanye neminye imidiya yenqubo, enomphumela omuhle wokuhlanza.

2. Isisindo somkhiqizo okhanyayo, amandla aphezulu emishini, nokumelana okuphansi

Isisindo sokunqwabelanisa semikhiqizo yokugcwalisa i-ceramic elula singama-280-350kg/m3, ephansi kakhulu kunomthamo wokupakisha wamafayili ajwayelekile ajwayelekile. I-porosity yokunqwabelanisa yomkhiqizo ingu-≥ 72%, i-porosity ebonakalayo ingu-≥ 15%, futhi isamba se-porosity singaphezu kwama-85%. Imaski inezinzuzo zesisindo esilula, umthwalo omncane, ukumelana okuphansi kokusebenza, nokucindezela okuncishisiwe kombhoshongo ogcwele.

Njengokupakishwa okuhlelekile, umkhiqizo unokumelana kombhoshongo owomile okungaphansi kwekholomu yamanzi engu-50mm kanye nokumelana nokusebenza okungaphansi kwekholomu yamanzi eyi-100mm kumbhoshongo wokuwasha we-naphthalene nge-flux yegesi engu-50000 m3 / ihora, okwenza kungabi lula ukuvinjelwa futhi kunqobe ububi bokuphuka kalula nokuvinjelwa kwezigcwalisi ezixekethile.

3. I-coefficient yokudlulisa ngobuningi, indawo enkulu ephumelelayo, nomphumela omuhle wokuhlukanisa

Isilinganiso sokusebenza kwezithako ze-ceramic ezikhanyayo yi-Tianjin University sibonisa ukuthi umkhiqizo une-coefficient yokudlulisa ngobuningi, okuyizikhathi ezingu-2.2 kunezinye izigcwalisi. Ukwengeza, ngemva kokugcwaliswa kokugcwalisa i-ceramic yokukhanya, imilenze engu-6 kuphela eseduze yokusekela ihlangana ukuze yenze indawo engasebenzi, futhi ukudluliswa kwe-gas-liquid kuyindlela yokuxhumana "ngaphezulu". Ngaphezu kwalokho, isigcwalisi se-ceramic esikhanyayo siyi-ceramic yekhekheba lezinyosi ezincane ezinendawo encane kanye nendawo ye-droplet yendawo, okwenza indawo ephumelelayo yokugcwalisa ibe mkhulu kune-99.5%, okuholela ekuhlukaniseni kanye nemiphumela yokuhlanza.

4. Izithako ze-ceramic ezikhanyayo zinokumelana nokuguga okuqinile, ukumelana nokugqwala, nempilo ende yesevisi

Umshini wokugcwalisa we-ceramic okhanyayo unokumelana nokushisa okuhle, ukumelana nomlilo okufika ku-1400 ℃, futhi amelana nokupholisa nokushisisa ngokushesha; Ngaphezu kwalokho, isigcwalisi esivamile se-ceramic light light sine-asidi enhle kakhulu nokumelana ne-alkali, impilo ende yesevisi, futhi ayijwayele ukuguga.

5. I-filler yonke ye-ceramic inesakhiwo senoveli, ingasikwa, futhi kulula ukuyigcwalisa

Uchungechunge olujwayelekile lwe-ceramic filler lungakwazi ukusikwa futhi luhlanganiswe embuthanweni, olungelona kuphela ukugcwalisa, kodwa futhi uvumela yonke indiza yokugcwalisa ukuthi isetshenziswe. Amanye ama-filler avamile, ngenxa yemvelo yawo yokungasiki, nakanjani anezikhala zosayizi abahlukahlukene ezizungeze umbhoshongo, okuholela ekugelezeni okukhulu kodonga kanye ne-groove, okungathinta ukusebenza kahle kokusetshenziswa ngamazinga ahlukahlukene.

Kafushane, ukupakishwa kwe-ceramic elula kuxazulule ngempumelelo ukungqubuzana phakathi kwe-porosity nendawo ethile, okungekho lula ukuvimba umbhoshongo kodwa futhi inokusebenza okuhle, okwenza kube ukukhetha kwabasebenzisi bombhoshongo wokugcwalisa.