2022-07-29

1. Ukusebenza kahle kokuhlukaniswa kokupakisha okuhlelekile kuphezulu, futhi izinga lokukhipha lombhoshongo wokulungisa liphezulu. Amazinga okukhipha umoya-mpilo ne-nitrogen emishini yokuhlukanisa umoya ahlukaniswe abe izinhlobo ezimbili: izinga lokukhishwa kwesethi ephelele yemishini kanye nezinga lokukhishwa kombhoshongo wokulungisa. Ngenxa yezinga lokukhishwa kwesethi ephelele yemishini kanye nomthamo wemishini yokuhlukanisa umoya. Ukukhishwa kwemikhiqizo ewuketshezi kuhlobene nezinye izici. Kunzima ukukala ukusebenza kahle kokuhlukanisa okuphezulu kokupakisha okuhlelekile. Izinga lokukhishwa kwekholomu yokulungiswa kanye nezinga lokukhishwa kwe-argon lingamela kangcono izinga lokuklama lesitshalo sokuhlukanisa umoya. izinsiza ezincane. Izinga lokukhishwa komoyampilo wombhoshongo wawo wokulungisa selifinyelele ngaphezu kwama-99%; izinga lokukhishwa kwe-argon lifinyelele ku-79%.

Inani lokusebenza kokuqukethwe komoya-mpilo ku-nitrogen ye-sewage kumbhoshongo ongaphezulu kuyinkomba eyinhloko yezinga lokukhishwa kokulungisa nokukhipha. Isilinganiso sangempela sibonisa ukuthi okuqukethwe kwe-oxygen ku-nitrogen ye-sewage kungaba ngaphansi kuka-0.1%, futhi kuze kufike ku-150-200x10-4%.

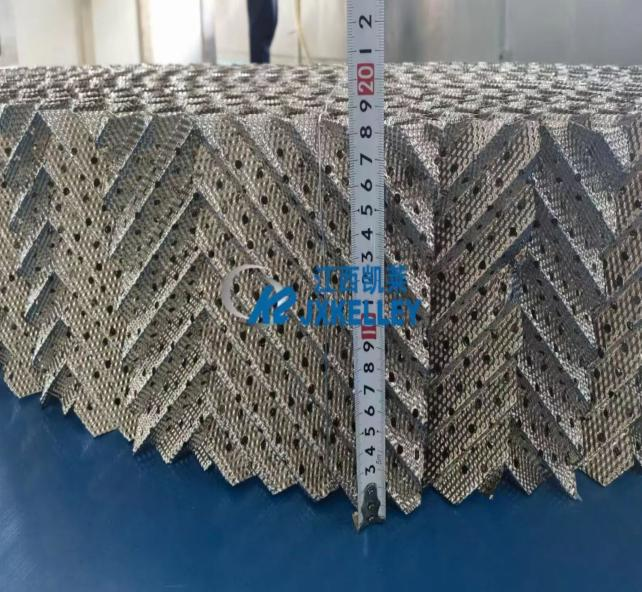

Ikholomu engenhla yokupakisha okuhlelekile kanye nekholomu ye-argon engcolile inokusebenza kahle kokuhlukana okuphezulu, okuwumphumela wengcindezi yabo yokusebenza enciphe kakhulu. Ukwehla kwengcindezi yokusebenza, kukuhle kakhulu ukuhlukaniswa kwe-oxygen, i-nitrogen ne-argon, nokuhlukaniswa kwe-oxygen ne-argon. . Ngokuvamile, izinga lokukhipha umoya-mpilo lingakhuphuka ngo-1% ukuya ku-3%; izinga lokukhishwa kwe-argon lingakhuphuka ngo-5% kuya ku-10%.

Izinga lokukhishwa kombhoshongo olungisayo nalo lincike kakhulu kumthamo womoya owandisiwe ongena embhoshongweni ongaphezulu, onomthelela omkhulu ekukhishweni kwe-argon. Ngakho-ke, ukusebenza kahle kwe-isentropic kwe-turboexpander kanye nesilinganiso se-booster se-booster kukhuphuka ngokuqhubekayo. , kuyisihluthulelo sokwandisa izinga lokukhishwa kwekholomu yokugcoba.

2. Isikhala sokupakisha okuhlelekile sikhulu, umthamo wokukhiqiza mkhulu, futhi ububanzi bombhoshongo buncishisiwe ukuze kube lula ukuhamba.

I-porosity yokupakisha okuhlelekile ingafinyelela ngaphezu kwama-95%. Kukholomu yepuleti lesisefo, indawo yepuleti le-orifice ithatha cishe u-80% wesigaba esiphambanayo sekholomu, futhi izinga lokuvula licishe libe ngu-8 kuya ku-12%, elingaphansi kakhulu kwezinga lokudonsa komoya lesendlalelo sokupakisha. Ngomthwalo ofanayo, isilinganiso sobubanzi bekholomu yekholomu epakishiwe Umbhoshongo wethreyi yesisefo mncane; ngokuvamile, indawo yayo ye-cross-sectional i-~ 70% kuphela yombhoshongo we-sieve tray, enenzuzo ekuthuthweni kwezitshalo ezinkulu zokuhlukanisa umoya.

3. Ukupakisha okuhlelekile kunomthamo omncane wokubamba uketshezi, isilinganiso esikhulu sokusebenza se-fluid-to-gas nokunwebeka, nezimo zokusebenza ezishintsha ngokushesha.

Umthwalo wokusebenza kwemibhoshongo ye-sieve tray ukhawulelwe ukuvuza kwesisefo kanye nesivinini sokukhukhula okuwuketshezi, kuyilapho imibhoshongo epakishiwe ilinganiselwe kuphela isivinini sokukhukhula okuwuketshezi, ngakho-ke imithwalo yabo yokusebenza ingahluka phakathi kobubanzi obuhlukahlukene, futhi ububanzi bomthwalo wokuklama wemibhoshongo epakishiwe bungafinyelela ku-40% ~120%, ukuphuma komoya-mpilo kombhoshongo ongaphezulu we-3mration/200 yesitshalo sokupakisha se-shaigh I-Iron and Steel No. 5 Plant ingalungiswa ngaphakathi kwebanga elingu-9000~14000mm3/h, futhi ububanzi bokulayisha bokusebenza bungama-75%~117% kuphela.

Ngenxa yoketshezi oluncane olubambekayo lombhoshongo opakishiwe, ngokuvamile luwu-1% kuya ku-6% kuphela wevolumu yombhoshongo, kuyilapho ukubamba uketshezi kombhoshongo wethreyi yesisefo kungu-8% kuya ku-N% wevolumu yombhoshongo. Isikhathi sokuhlala sifushane futhi ukwehla kwengcindezi yokusebenza kuncane, okubuye kuhambisane nokusebenza kwezimo zokusebenza eziguquguqukayo, kodwa kufanele kuqinisekiswe ekusebenzeni kwangempela kwezimo zokusebenza eziguquguqukayo esikhathini esizayo.

4. Isikhathi sokuqalisa socingo sifinyezwa kakhulu

Inqubo yokuqalisa imboni yokuhlukanisa umoya ayiwona umsebenzi wokuphuma komkhiqizo, ngakho ukufinyeza isikhathi sokuqalisa kungenye yezindlela zokuthi isitshalo sokuhlukanisa umoya songe amandla futhi sinciphise ukulahlekelwa. Ngemva kokusebenzisa ukupakisha okukhona okuhleliwe, inani loketshezi elibambayo ngesikhathi sokulungiswa okuvamile liyancipha kakhulu, elinciphisa kakhulu isikhathi sokuqalisa sesitshalo sokuhlukanisa umoya.

Isikhathi sokuthumela: Aug-01-2022