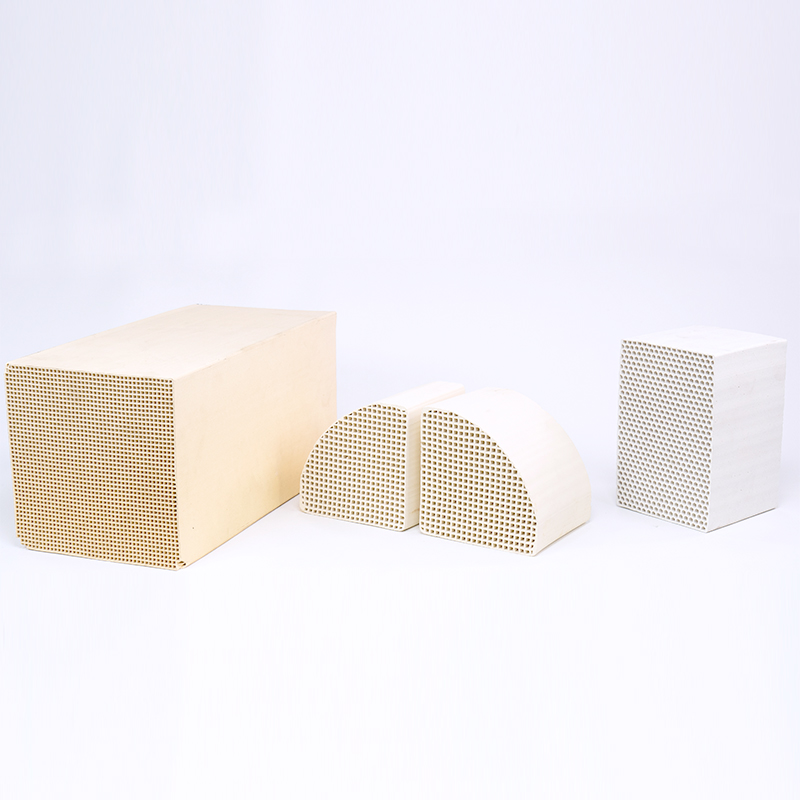

I-RTO - I-Heat Exchange Honeycomb Ceramic

Imisebenzi

1.Yehlisa ukulahlekelwa okushisayo kwegesi yokukhipha, futhi uthuthukise ukusebenza kahle kukaphethiloli ukuze wonge amandla njengoba.

2.Thuthukisa izinga lokushisa elivuthayo ngokusekelwe kumbono, thuthukisa ukushiswa komkhathi, ukuhlangabezana nezinga lokushisa eliphezulu lezinto ezishisayo khulisa uphethiloli we-calorific ephansi, ikakhulukazi ububanzi bokusetshenziswa kweziko eliqhumayo, thuthukisa ukusebenza kahle kukaphethiloli we-calorific futhi unciphise ukukhishwa kwegesi yamalahle enenani eliphansi le-calorific.

3.Thuthukisa imigomo yokushintshisana ngokushisa ezindlini, ukhuphule ukuphuma kwemishini, uthuthukise ikhwalithi yemikhiqizo futhi unciphise ukutshala kabusha okokusebenza.

4.Yehlisa ukukhishwa kwe-exhaust yemishini eshisayo, unciphise ukungcoliswa komoya futhi uthuthukise imvelo.

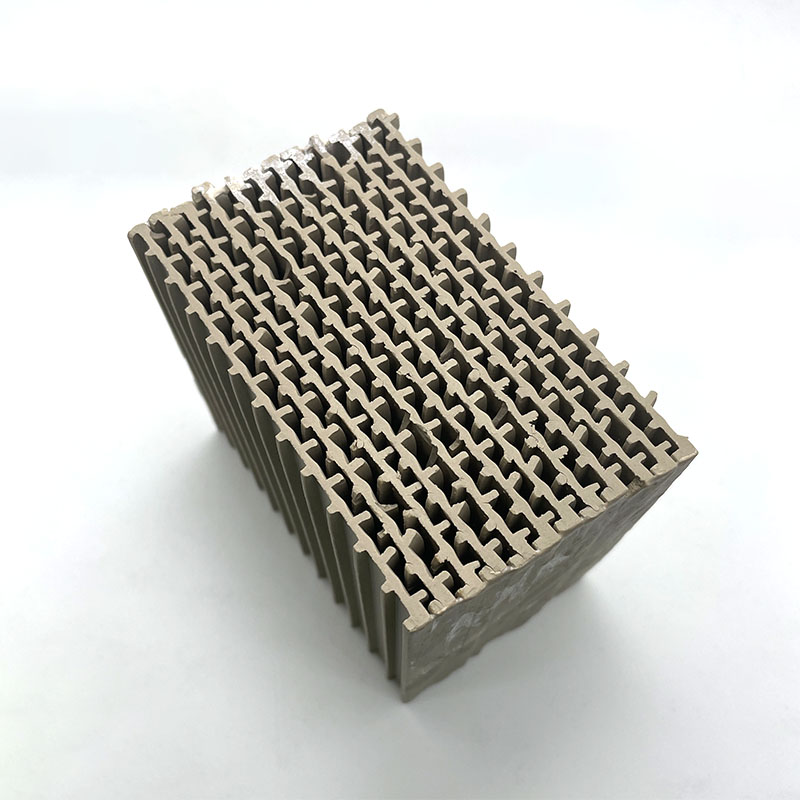

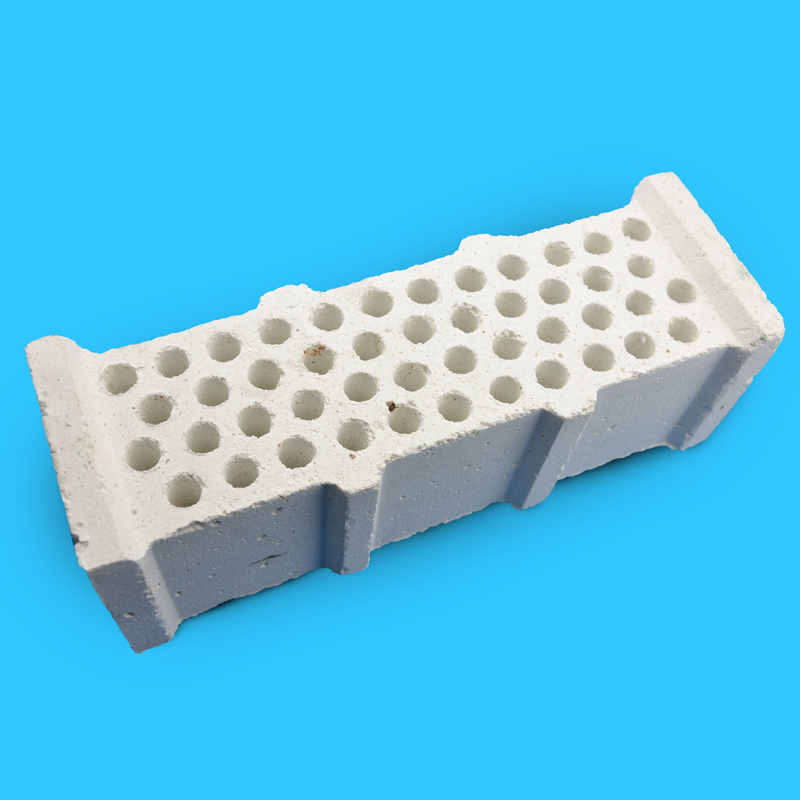

Izici

Izici ze-honeycomb ceramic regenerator yilezi ezilandelayo: zinokunwetshwa okuphansi kokushisa, umthamo wokushisa othize othize, indawo ethile ephezulu, ukwehla kwengcindezi ephansi, ukumelana nokushisa okuphansi, ukuguquguquka okuhle kokushisa, ukumelana nokushisa okushisayo nokunye okuningi. Ngakho-ke, ezimbonini ze-metallurgy namakhemikhali, isetshenziswa njenge-HTAC, ngenkathi sihlanganisa ukugaywa kabusha kokushisa kokukhishwayo, ukushiswa okuphakeme okuphumelelayo nokunciphisa i-NOx. Iba isilondolozi samandla sangempela futhi yehlise i-Nox.

Izinto: I-Alumina, i-Alumina Eminyene, i-Cordierite, i-Dense Cordierite, i-Mullite, i-Corundum Mullite nezinye

Isicelo

I-ceramic yekhekheba lezinyosi iyisihluthulelo nengxenye eyinhloko yokugcina ukushisa kobuchwepheshe bokushisa ukushisa okuphezulu (ubuchwepheshe be-HTAC). Isetshenziswe kabanzi ezindaweni zokushisa ezehlukene ze-push-steel, iziko lokufudumeza ezihambayo, izithando zokushisa ukushisa, iziko lokubumba, iziko elincibilikayo, ama-ladle/tundish roasters, izitofu zokucwiliswa, izibasi zamashubhu akhazimulayo, kanye nezithando zohlobo lwensimbi embonini yemishini yensimbi. Isithando somlilo, isithando somlilo esishisayo; izithando ezihlukahlukene ze-ceramic kanye nezingilazi ezihlukahlukene zengilazi embonini yezinto zokwakha; amaziko ahlukahlukene okushisa amashubhu, izithando zomlilo eziqhekekayo nezinye iziko lezimboni embonini ye-petrochemical.

Imininingwane

100x100x100, 100x150x150, 150x150x150, 150x150x300mm nokunye

Isibalo semigodi: 25x25, 40x40, 43x43, 50x50, 60x60 nabanye

Ubukhulu

| Ubukhulu (mm) | Amaseli (N×N) | Ukuminyana kwamaseli (CPSI) | Ububanzi Besiteshi (mm) | Ukuqina kodonga lwangaphakathi (mm) | Free Cross Section (%) |

| 150×150×300 | 20×20 | 11 | 6.00 | 1.35 | 64 |

| 150×150×300 | 25×25 | 18 | 4.90 | 1.00 | 67 |

| 150×150×300 | 32x32 | 33 | 3.70 | 0.90 | 63 |

| 150×150×300 | 40×40 | 46 | 3.00 | 0.70 | 64 |

| 150×150×300 | 43x43 | 50 | 2.80 | 0.65 | 64 |

| 150×150×300 | 50×50 | 72 | 2.40 | 0.60 | 61 |

| 150×150×300 | 59x59 | 100 | 2.10 | 0.43 | 68 |

Ukwakheka Kwamakhemikhali

| Into | I-Cordierite | Mullite | I-Alumina Porcelain | High Alumina Porcelain | Corundum |

| Al2O3 | 33 | 65 | 54 | 67 | 72 |

| SiO2 | 58 | 30 | 39 | 23 | 22 |

| MgO | 7.5 | <1 | 3.3 | 1.7 | <1 |

| Abanye | 1.5 | 14 | 3.7 | 8.3 | 5 |

Izakhiwo Zomzimba

| Into | I-Cordierite (Imbobo) | Mullite | I-Alumina Porcelain | High Alumina Porcelain | Corundum | |

| Ukuminyana(g/cm3) | 1.8 | 2.0 | 1.9 | 2.2 | 2.5 | |

| Ukumuncwa kwamanzi (%) | 23 | 18 | 20 | 13 | 12 | |

| I-Coefficient of Thermal Expansion(×10-6K-1) (20~800℃) | ≤3.0 | ≤6.0 | ≤6.3 | ≤6.0 | ≤8.0 | |

| Ukushisa Okuthile (J/Kg.K) (20~1000℃) | 750-900 | 1100-1300 | 850-1100 | 1000-1300 | 1300-1400 | |

| I-Thermal Conductivity (W/mk) (20~1000℃) | 1.3-1.5 | 1.5-2.3 | 1.0-2.0 | 1.5-2.3 | 5; 10 | |

| Ubukhulu. Izinga Lokusebenza.(℃) | 1200 | 1400 | 1300 | 1400 | 1650 | |

| Amandla e-Axial crushing (MPa) | Yomile | ≥11 | ≥20 | ≥11 | ≥22 | ≥25 |

| Ukucwiliswa | ≥2.5 | ≥2.5 | ≥2.5 | ≥2.5 | ≥2.5 | |